The weekend after Thanksgiving we took the family up to Waco to a harvest festival put on by a group of anababtists who farm using traditional (non-mechanized) methods, teach traditional crafts, and generally do things a bit slower than the general population. Along with selling their wares, they teach a series of seminars on self sufficiency, skills like blacksmithing and beekeeping, animal husbandry, etc… It’s interesting and fun to spend a few days wandering, watching, and listening. This year, Liz came home with a few “good ideas.” Good ideas generally mean work… lots of it.

We’ve been meaning to put … Read the rest

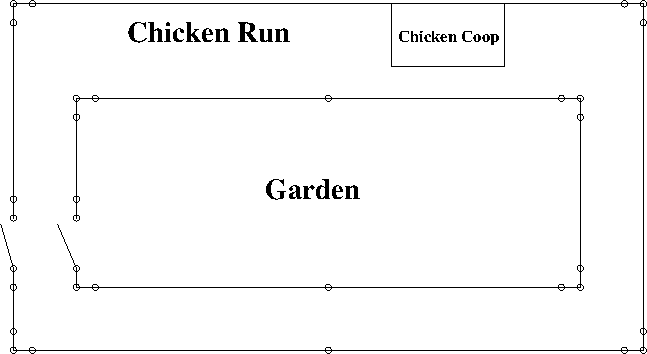

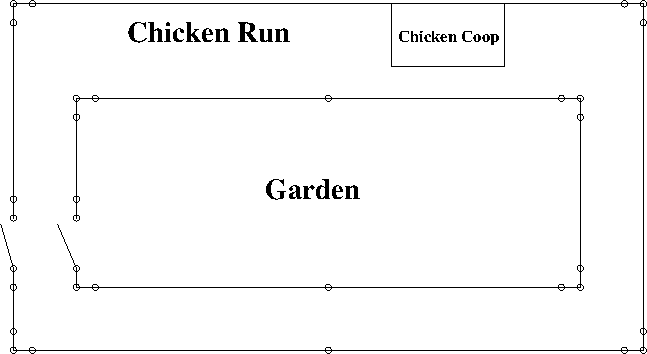

Every project we’ve done so far in the “yard” has been geared towards something that produces food or is food. So far projects have included things like the barn, fence, chicken coop, electric to the barn and coop, water to the animals, etc… The only thing I’ve done to the yard is to cut back the brush and let wild grasses grow in. Not much of a yard, and not particularly good at keeping the mud down when it rains.

Now that some of the major projects are done, and all the animals have homes and water, I decided to … Read the rest

Liz has never really liked the idea of an “inside dog,” coyotes were wreaking havoc on our chickens, and we were planning on going on a family vacation for two weeks and leaving the Dog outside to “protect” the other animals and to make it much easier on the family who was going to be feeding and watering the animals. The dog would need somewhere to get out of the weather. Because the barn is behind the back pasture fence and I don’t like the idea of the dog hanging out in the chicken coop I decided the best option … Read the rest

I had thought I had taken pictures of the chicken coop while I was building it. True to form, I got busy and forgot. So… I guess you get to settle with a picture of Michael doin’ what he spends a lot of time doing: Playing with chickens.

Liz decided she wanted a lot of fresh eggs, which translated into an order of 40 chicks (straight run, so about half would end up in the stew pot as young roosters). The only problem is that you can’t use a standard back-yard chicken coop for those kinds of numbers. To … Read the rest

This is a stub for me to write about my (bad) experience with the Tongling Strand Woven Bamboo flooring we installed in our house. The quick and dirty version is simple. It scratches very easily, and scratches are highly visible against the dark color. It shrunk enough to separate the joints in the middle of the room and leave a 1/2 inch gap in spite of following their recommended maximum span, acclimation time and procedure, and floor preparation, and is terribly difficult to keep clean. If you are a little old lady who never goes outside, wears felt-soled slippers all … Read the rest

The outside of the house is basically finished.

Here is a small shot of the living/kitchen area. The pantry door is the first to the left. The french doors open into the office.

This week cabinets are being stained and installed, tile floor is being put down in the bathrooms and laundry room, and light fixtures and fans are going in. The front door is now on and the garage door will be coming soon. Peter has decided to install the wood flooring in the main area to save us nearly $3000 in labor costs.

I have been looking up … Read the rest

Peter's Prose, Poetry, and Random Ramblings